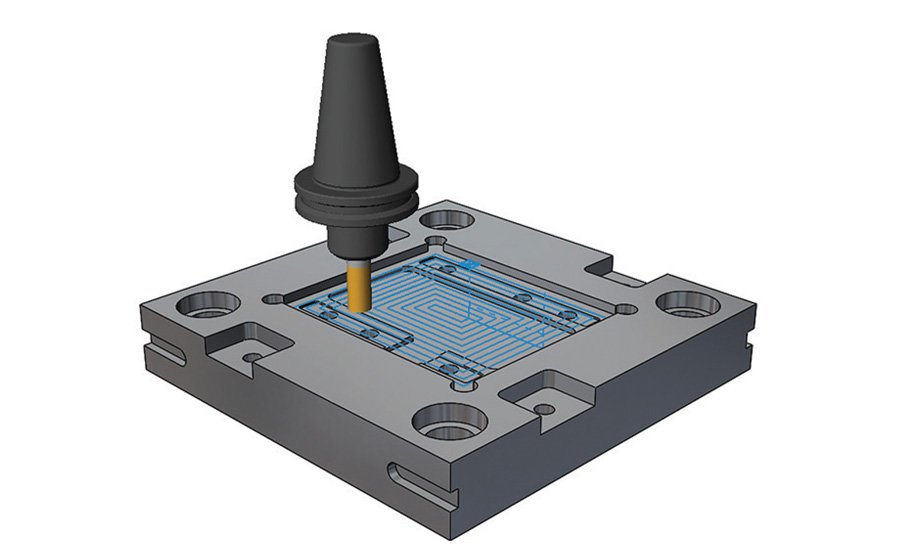

The flowline path option for cut across generates a tool path perpendicular to the flowlines as shown below. In this case, that means it cuts along the X-axis and Z-axis. The flowline “cut along” option generates a tool path parallel to the flowlines as shown below. The tool path is then cut either parallel or perpendicular to the curves. What flowline does is create a tool path based on two user-defined curves. Usually, we select this option when working with round shapes, as it creates a spiral-out style tool path, based on a user-defined center point location.įlowline pattern is the final tool path pattern option. Next, we have the spiral pattern project operation. The radial pattern generates a toolpath in a radial pattern into or out from a user-defined center point and can be limited to a defined angular range. Commonly, we use a radial pattern for round shapes due to its unique characteristics for controlling the toolpath. The radial pattern is your third toolpath pattern option. These show the tool path when the mill is not in contact with the part. In particular, I want to draw your attention to the dotted lines. Here’s an example of what that could look like. One way to use the slice pattern is for machining non-vertical areas of a part when you are trying to achieve semi-finishing and finishing of a 3-axis part feature. Additionally, you can also control the angle of the cut with additional pattern options. With a slice pattern, you define a series of linear and parallel cutting paths across the feature of the part. Slice is one of the pattern tool path options. The Four Pattern Project Operation Options Once again, each pattern has unique characteristics, making them appropriate for semi-finishing and finishing selected areas or even the entire model. The Pattern Project operation could also be a multi-surface finishing cycle that removes material based on the selected pattern. Each pattern has unique characteristics that make them appropriate for semi-finishing and finishing selected areas or the entire model.

Generally, these patterns are projected onto the model surfaces with the tool stepping over using a constant value for X and Y.

Those type options are slice, flowline, radial, and spiral. The Pattern Project operation is a 3-axis finishing operation type that removes material based on the selected pattern.

In this article, I will be focusing on the toolpath control options you get when using the Pattern Project strategy included with CAMWorks Milling Standard. From different pattern type options to the granular options within each pattern, there’s a lot to digest. CAMWorks offers several options when setting up your tool path.

0 kommentar(er)

0 kommentar(er)